Textile Dyeing Machines

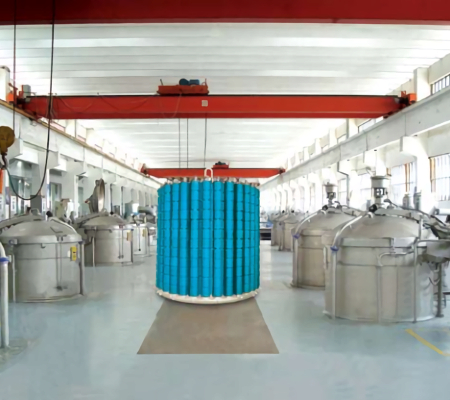

A.T.E. Group provides a comprehensive and forward-thinking range of textile dyeing machines, meticulously developed to meet the dynamic needs of the modern textile industry. Whether you're dyeing yarns, fabrics, or specialty textiles, A.T.E.'s machines deliver consistent, high-quality results with exceptional precision. Designed with cutting-edge technology, these dyeing systems ensure even colour application and optimal colour penetration, crucial for upholding product quality and customer satisfaction. A key strength of A.T.E.’s textile dyeing machines lies in their energy-efficient design, which not only reduces operational costs but also supports eco-friendly manufacturing. With optimised liquor ratios and advanced process controls, these machines consume significantly less water and energy compared to conventional systems, aligning with sustainable production goals. Engineered to handle a wide range of materials including cotton, synthetics, and blended fabrics. A.T.E.’s textile dyeing machines support various dyeing techniques, from high-temperature processing to low-liquor ratio methods. Their robust build ensures long-lasting reliability, while user-friendly controls simplify operation, reducing the need for manual input. A.T.E.'s textile dyeing machines are strategic assets that help textile manufacturers enhance quality, boost productivity, and remain competitive in an increasingly demanding market.

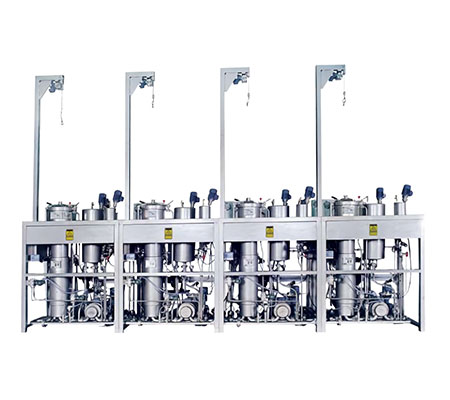

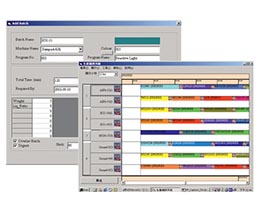

A.T.E.’s textile dyeing machine product portfolio includes Fong’s Allwin Plus, a high-temperature, high-pressure machine ensuring consistent dyeing quality. Labwin, featuring advanced airpad technology, delivers impeccable dyeing results. Microwin is ideal for laboratory sample dyeing, while Miniwin utilises unique wave dyeing technology for perfect dyeing quality. Superwin is a single flow dyeing machine, and Viewtex offers world-class technology for managing dye processes and production schedules. The EP pressing machine is versatile, handling packages in cones or tubes, and loose stock like cotton, wool, and tops. The dyeing dispensing system from Color Service is optimal for package processing

A.T.E.’s wide range of textile dyeing machines caters for different dyeing formats, including yarns in cone, tube, hank, or beam forms. These systems maintain consistently low liquor ratios, promoting efficient use of resources while ensuring superior dye uptake for uniform and vibrant results. Customers can choose between air-pad and fully-flood versions, enabling precise matching to specific dyeing needs. Innovative features like the AIR+ system and high-temperature drain significantly cut down process times and reduce the consumption of cooling water and energy—key factors in sustainable operations. These textile dyeing machines are designed for high-capacity performance, these machines can handle large volumes of fabric while maintaining consistent colour distribution throughout the batch. Their versatility makes them suitable for a wide range of fabric types and dyeing methods, delivering excellent results every time. With a focus on reliability and ease of use, A.T.E.'s textile dyeing machines feature intuitive interfaces and automated controls, minimising human intervention and potential errors. The combination of durability, smart design, and efficiency makes them a valuable investment for textile processors looking to improve throughput and product quality.