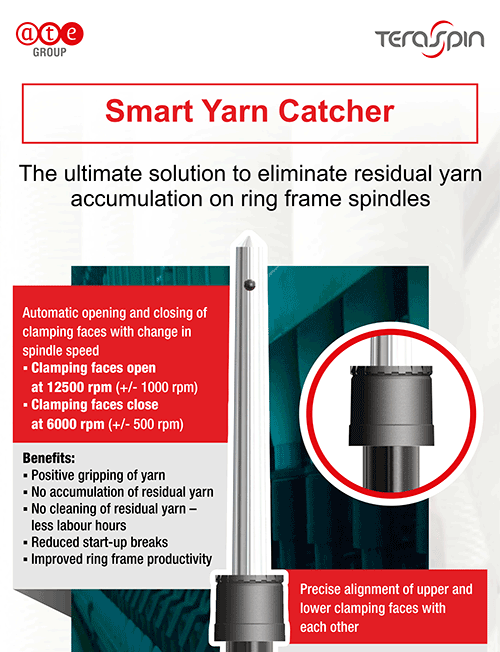

Spindles With Smart Yarn Catcher

User-friendly yarn clamping

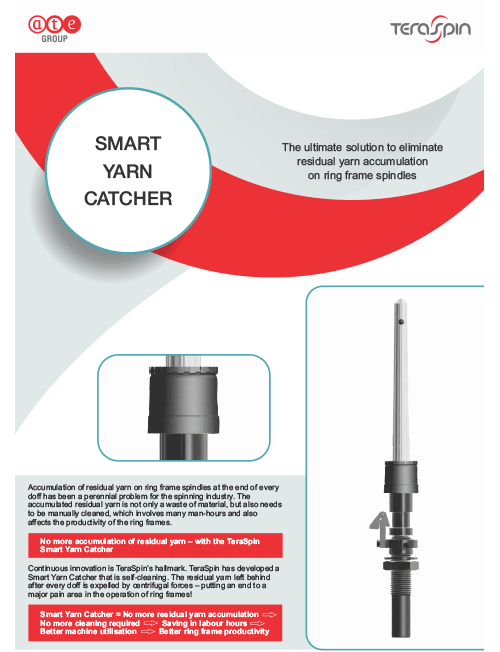

Accumulation of residual yarn on ring frame spindles at the end of every doff has been a perennial problem for the spinning industry. The accumulated residual yarn is not only a waste of material but also needs to be manually cleaned, which involves many man-hours and reduces the productivity of the ring frames.

TeraSpin has developed a Smart Yarn Catcher (SYC) that is self-cleaning. The residual yarn left behind after every doff is expelled by centrifugal forces – putting an end to a major pain area in the operation of ring frames!

Many trials have shown no yarn accumulation on SYC units even after 45 days of continuous running. With optimisation of process parameters, one can truly achieve performance free of residual yarn accumulation.