Warp Knitting Machines

Knitting is broadly classified into warp knitting and weft knitting. The tricot and raschel warp knitting machines are the specialised technology in warp knitting to manufacture a variety of knitted fabrics mainly by using synthetic filament yarns. The weft knitting, also known as circular knitting, is mainly for hosiery applications with single and double-knit technologies which can handle almost all types of spun and filament yarns. Warp knitting machines play a vital role in the textile industry by facilitating the mass production of knitted fabrics with various properties and applications. They are extensively useful in the manufacturing of clothing, lingerie, technical textiles, as well as home textiles such as curtains and lace.

Overview section

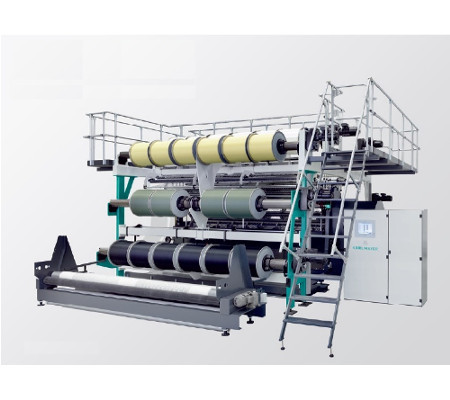

KARL MAYER, a well-known producer and technology leader in warp knitting, is highly regarded for its exceptional quality and cutting-edge solutions. Among the extensive portfolio of warp knitting machines, they offer a complete range of tricot, raschel, lace, and double-needle bars along with warp preparation solutions. KARL MAYER warp knitting machines are specifically designed to meet diverse fabric production requirements, ranging from delicate tricot fabrics to intricate lace and technical textiles. These technologies are renowned for their dependable performance, efficiency, and adaptability in manufacturing a vast array of fabrics for various industries.

Depending on the intended end-use and fabric constructions as per applications, the tricot warp knitting machines are the best to choose with two, three, or four guide bars to produce a variety of designs and patterns and also by inserting weft for certain applications. Raschel warp knitting machines are versatile machines that can produce a variety of fabrics, including lace and curtain fabrics with high precision. In the raschel knitting technology, double-needle bars are mainly to produce 3D warp knitted textiles, spacer fabric, plush fabric, and seamless articles with or without a jacquard pattern. In this era of Industry 4.0, Karl Mayer has advanced with KM.ON cloud-based solution for their HKS machines, which provides unlimited design patterning possibilities.

.png)