Textile humidification plant

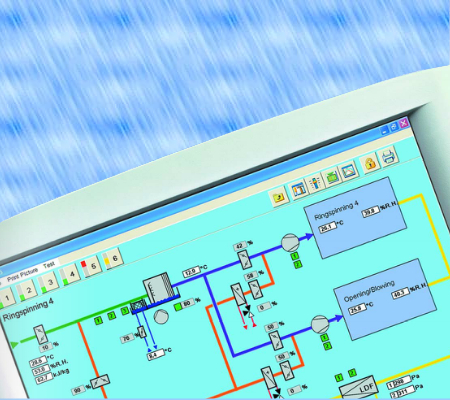

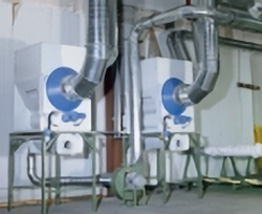

The textile humidification plant is employed to control humidity levels in diverse environments, such as manufacturing facilities, textile production sites, and clean rooms. Its humidifiers incorporate a range of technologies, including steam, evaporative, or high-pressure systems, tailored to meet the specific requirements of each application. The textile humidification plant is equipped with an advanced control system that automatically regulates the desired humidity levels, ensuring both reliability and efficiency. This may involve the use of sensors and automated mechanisms for real-time adjustments. The system features a method for evenly distributing humidified air throughout the textile humidification plant and facility, thereby maintaining uniform conditions and addressing localised humidity issues.

The air control systems focus on managing various aspects of air quality and circulation in textile mills, including ventilation systems that control the intake of fresh air and the removal of contaminants. The temperature control system is an integrated solution that manages temperature in conjunction with humidity control. Its filtration system is designed to remove particulates and pollutants from the air, thus improving overall air quality. These energy-efficient features aim to optimise energy usage, reducing operational costs and minimising environmental impact. Such systems are essential in industries where precise environmental conditions are vital for product quality, employee comfort, or compliance with regulatory standards