Dry Processing

Dry processing in textiles refers to the finishing stage where fabrics undergo treatments to achieve specific functional and aesthetic properties. Unlike wet processing, which involves water-based treatments, dry processing focuses on improving fabric performance through chemical and mechanical methods.

Dry processing is broadly categorised into chemical finishes and mechanical finishes.

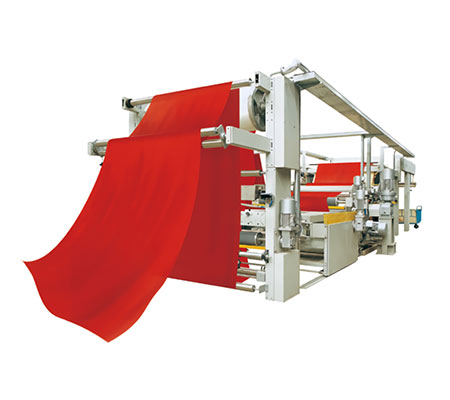

- Chemical finishes, such as water repellence, flame retardancy, or anti-bacterial properties, are applied using padder applicators or coating machines. These treatments are then cured and fixed using stenters and curing ovens, ensuring durability and effectiveness.

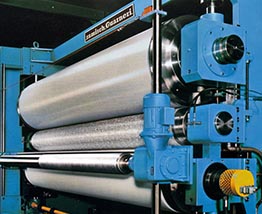

- Mechanical finishes include techniques like peaching, raising, and calendaring. Peaching creates a soft, suede-like feel; raising enhances warmth and texture by lifting fibres; and calendaring smooths the fabric through heated rollers for improved sheen and hand feel.

Each finish is tailored to meet specific end-user demands, whether for apparel, home textiles, or industrial use.

The final step in dry processing is shrinkage control, commonly achieved through sanforising, which stabilises fabric dimensions and ensures quality retention during consumer use.