PRODUCT

Stenter- Model 828

(TwinAir stenter frame range)

Monfongs 828 TwinAir stenter frame range is designed according to German technology and standards. It is a standard version for a range of applications such as dehydration, finishing, drying, cutting and heat-setting of woven and knitted fabrics. The machine's chain track can be adjusted according to the requirements of the manufacturer from a central control panel. Hi-tech stenter chains, fabric transport drives, and infeed combinations are just a few configurations, among many.

Manufactured by: Monforts Fongs Textile Machinery Co. Ltd, Hong Kong

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

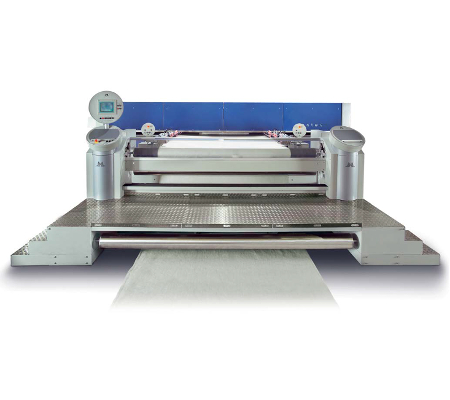

Key Features

- Qualitex 750 - full automation with teleservice and storage up to 10000 records

- TwinAir technology to regulate bottom and top nozzle independently

- Drawable easy chamber cleaning filters

- Drawable CAD stream nozzles for easy cleaning

- Isothermal zones

- Horizontally mounted radiators

- Individual chamber temperature controller

- 150 mm door insulation

- Individual width adjustment facility

- Lifelong lubrication-free width adjustment spindles

- Long-term lubricated chains

- Inlet and out J scray for non-stop operations

- Pneumatic lowering and lifting of finishing troughs and front tilting facility for easy cleaning

- Even pressure roller for finishing padder (model 6000)

- Crowned pressure roller for de-watering padder (model 5000)

- IE 2 class energy motors for fan motors

- Programmable invertors

- Aeromatik - for avoiding stoppage marks on fabric in sudden stoppages of machine

- Optional HR system

- Optional Monformatic process control system

- High productivity

- Low maintenance

- Low thermal energy and low electrical energy consumption

Your message was sent successfully. Thanks.