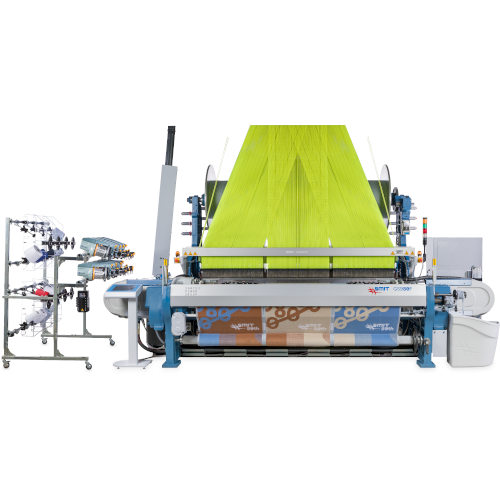

PRODUCT

Technical fabric weaving machine

(For manufacturing of technical textiles)

Smit technical fabric weaving machines are suitable for manufacturing a wide range of textiles for technical applications - from heavy conveyor belts to finest mesh for bolting cloth, as well as electronic boards, air bags, synthetic/metallic filters and much more. The front shed designed to avoid friction points and hard chromium-plated press rollers prevent wear on fibres. No guiding teeth on the warp means no friction on the warp yarn which ensures minimum stress on the warp. This is particularly useful when using glass fibres.

Manufactured by Smit S.r.l, Italy

-

FEATURES

-

BENEFITS

-

GET A QUOTE

-

Key Features

- Specialised for technical fabrics with patented weft insertion grippers and other technical features such as relevant control system, shed geometry, reed beat-up and warp control

- For glass fibres, regular weft insertion is ensured by special grippers that are designed to prevent wear

- For glass fibres, specific leno binding prevents fabric distortion

- Large range of yarn counts from (above 900 tex)

- Double warp feeding for increased capacity available

- For fabric used in heavy industrial applications, high precision is ensured by high warp tension, and modulated by special braking rollers

- For fabric used in heavy industrial applications, high cover factor thanks to a heavier, stiffer and stronger sley bar and supports for very dense fabrics

- Dynamic rapier control

- In airbag fabric manufacturing, highest cover factor with special full width temple for low cloth recoiling/high weft density

- In airbag fabric manufacturing, delicate yarn handling is ensured by special press rollers, no guiding teeth and laser warp stop motion to avoid friction on warp threads

- In bolting cloth, excellent control of weft density

- In bolting cloth, maximum precision in fabric thanks to dedicated sley bar movement, and special heald frames movement as well as minimum back and front shed angle

- In bolting cloth, low yarn stress thanks to special control of the weft selectors fingers

- For Aramid fibre: constant fabric properties ensured by back rests special surface coating on all warp friction points to avoid sticking on the yarn

- For Aramid fibre: knot-free sensors

- For Aramid fibre: grippers with special profile designed to avoid contact between the tape and the warp

-

Benefits

- Tailor-made for high performance and maximum productivity in technical textiles

- Functional, compact and user-friendly design

- Modular design developed for these machines and weft transport technology permit working widths of 140 to 360 cm with excellent insertion rates

- Suitable for the manufacturing of a wide range of fabrics: glass, carbon, high-precision printing and bolting, aramid, airbag, and industrial and heavy fabrics, among others

Your message was sent successfully. Thanks.