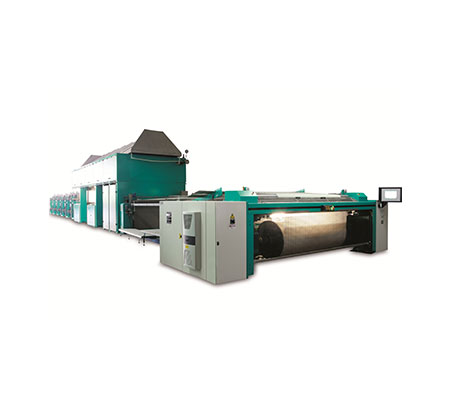

Textile Weaving Machine

Textile weaving is the foundation of fabric production, essential for turning yarns into a wide range of woven fabrics with different textures, designs, and functions. The textile weaving machines are designed to intricately interlace vertical (warp) and horizontal (weft) yarns, creating the unique patterns and structures that characterise textiles used in clothing, home goods, technical textiles, and more. The rapier weaving technology stands out for its versatility in utilizing various weft yarns to produce high-quality fabrics, including technical textiles. A.T.E.'s comprehensive lineup of warp preparation solutions underscore its commitment to assisting weaving mills with state-of-the-art technologies that improve efficiency, quality, and productivity. By collaborating with global leaders offering advanced equipment and systems, A.T.E. facilitates the seamless transformation of yarns into premium woven fabrics, meeting the diverse needs of the global textile sector. Our solutions offer innovative approaches to streamline warp preparation, enabling swift and cost-effective manufacturing processes while upholding the utmost standards of dependability and adaptability in weaving operations.

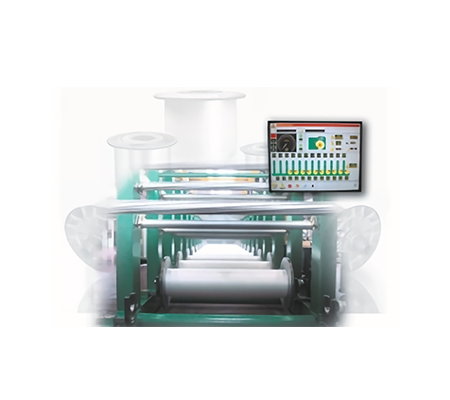

A.T.E. partners with industry leaders such as KARL MAYER to provide textile weaving machines, specialising in warp knitting and warp preparation technologies. KARL MAYER's innovations optimise the efficiency and quality of warp preparation procedures, guaranteeing accurate and uniform yarn preparation. In the weaving industry, A.T.E. delivers high-speed rapier weaving machines from SMIT, recognized for their durable performance and capability to work with a variety of fabrics. Luwa air engineering ensures optimal environmental conditions in weaving mills through effective humidification and air circulation, enhancing process efficiency. Moreover, A.T.E. offers MAG yarn and fabric lab equipment, along with Craftsman material handling and storage solutions and cloud-based real-time loom monitoring system from EcoAxis (a part of the A.T.E. Group).