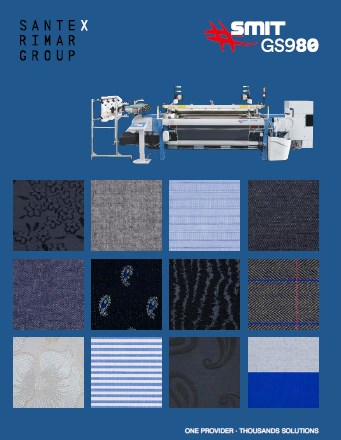

PRODUCT

GS980

(High speed shuttleless weaving loom for high quality production)

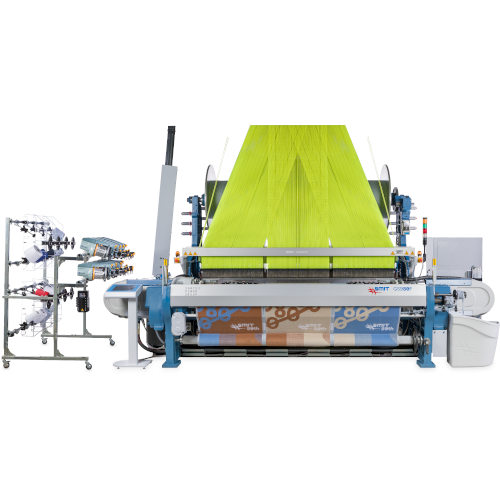

The SMIT GS980 is a well-proven product for the production of high quality fabrics for apparels, home textiles, technical applications and fabrics with exclusive yarns and patterns. The free flight ribbons, Leno-Force, and patented gripper system makes the GS980 an asset to any weaver. Its high efficiency, heavy torque motor allows the GS980 to operate at speeds of up to 1650 m/min, depending on style and machine width. The Smit GS980 is a good mix between low maintenance costs, high productivity, and low energy consumption.

Manufactured by Smit S.r.l, Italy

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Key Features

- Smart platform

- New Leno-Force system

- New patented grippers

- Software controlled e-cut

- High efficiency motor that generates high torque

- Rapier drive and optimized distribution of masses reduces vibration and noise

- Real-time monitoring of weft movement and behaviour during the weft insertion

-

Benefits

- Free flight ribbons system and optimized shed geometry ensure top fabric quality by avoiding marks, warp yarn wear from friction between hooks and yarns

- New direct drive and short kinematic arrangement ensures low vibration and noise

- Warp let-off, electronic take-up, and main direct drive are simultaneously controlled to ensure maximum accuracy

- Excellent and stable fabric quality for whatever yarn count and pattern type

- New, efficient lubrication system with forced oil circulation guarantees low energy dissipation in mechanisms, avoiding the adoption of additional oil cooling systems; extended lubricant life time reduces maintenance costs

- New shed-crossing phase setting from touch screen terminal shortens set-up and start-up times considerably

Your message was sent successfully. Thanks.