Rapier looms

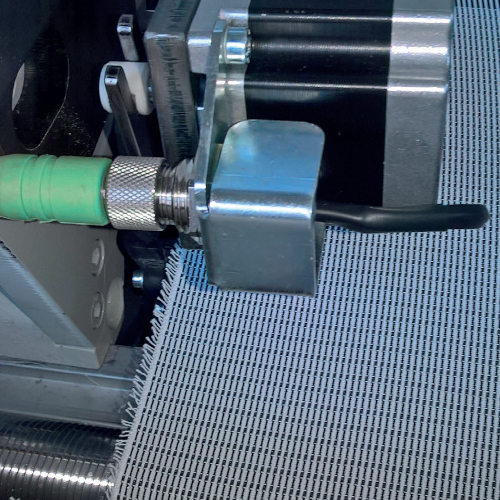

These rapier looms feature advanced shuttlerless technology, providing flexibility, and are outfitted with newly designed patterned grippers that have a reduced cross-section, thereby maximising efficiency for all types of yarn. The newly optimised shed geometry guarantees impeccable fabric construction and high efficiency, even at peak production rates. Additionally, these rapier looms are powered by high-efficiency brushless motors with permanent magnets, which are distinguished by their superior power factor and minimal heat generation. The design includes a lower center of gravity and a compact external width, enhancing stability and minimising vibrations during high-speed operation. Furthermore, the accessibility for the weaver is improved, allowing for quicker interventions. The compact structure of the rapier looms machine features a new and optimised mass distribution, ensuring optimal stability and effective reduction of dynamic loads on the floor.