PRODUCT

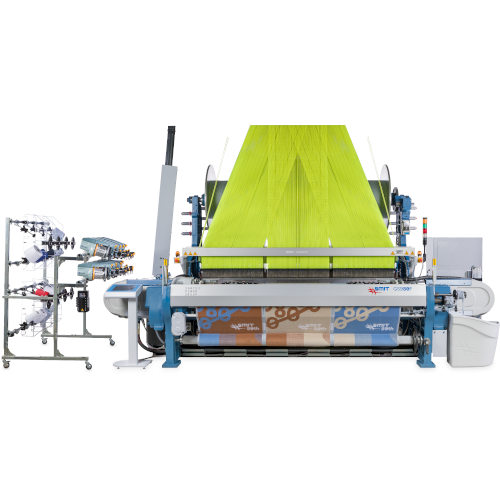

2FAST

(Flexible Advanced Shuttle-less Technology)

The Smit 2FAST is a high speed, shuttle-less rapier loom in which the filling/weft yarn is carried through the shed of warp yarns to the other side of the loom by two finger-like carriers called rapiers. The rapiers are mounted on flexible flying-ribbons, which exchange the weft in the centre. This enables the 2FAST to operate at speeds of up to 1650 m/min, depending on the style and machine width. The 2FAST is a good mix between low maintenance costs, high productivity, low energy consumption, and features Industry 4.0 compatibility.

Manufactured by Smit S.r.l, Italy

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Key Features

- Custom-made self-retaining grippers which are easily adjustable and remain stable while weaving

- Free Flight Ribbons System without ribbon guide hooks; ensures a “clean shed”

- New short mechanical transmission with low energy consumption

- High efficiency brushless motor with permanent magnets with high power factor and low heat generation

- Balance shaft for stable running - counter-rotating main shaft and cam shaft, with optimised transmission ratio, to minimise the torsional loads transmitted to the structure during rush start and stop

- New and optimised distribution of masses to ensure the greatest stability and the most effective reduction of dynamic load on the floor

- Frame stiffness +20%

- Low centre of gravity and compacted machine external width ensures increased stability and reduced vibrations at high speed

- Easy accessibility for the weaver enables quick intervention if need be

-

Benefits

- Optimised shed geometry ensures perfect fabric construction and high efficiency

- Compact design; space saving in the weaving department

- Grippers ensure top efficiency while transferring any type of yarn

- Low energy consumption and high running consistency

- Direct drive reduces energy consumption

Your message was sent successfully. Thanks.