PRODUCT

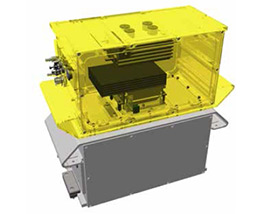

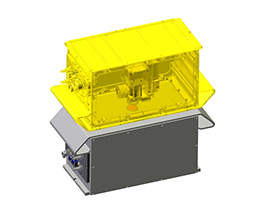

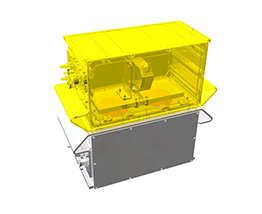

Calipro DML Non-contact Thickness Gauge

The thickness of the product is determined by evaluating the difference between the two measured values. This is done by the Calipro DML's built-in microprocessor, which at the same time synchronises the upper and lower lasers and, on the certain versions, processes in real-time the data measured by the numerous temperature sensors, which compensate for any temperature-related dimensional changes in the housing.

Manufactured by: Mahlo GmbH & Co. KG., Germany

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Key Features

- Non-contact, non-destructive, and ultra-precise measurement of online product thickness

- Available in several configurations to suit various accuracy requirements

- Can gauge either at one side against a reference roller or on both sides

- High sampling rate and resolution of the cross-web profile

- Since the gauge is able to traverse, it indicates the thickness of the product from edge to edge

- Determines the thickness of a web or sheet directly without reference to product density

- Non-contact measurement has no adverse effect on either product quality or the manufacturing process

- Insensitive to variations in.the surface of the product, thus ensuring a high degree of measurement stability

- Highly responsive

Your message was sent successfully. Thanks.