PRODUCT

PCS-12

(Pattern control system)

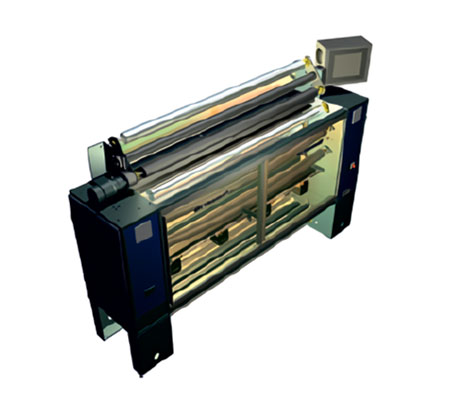

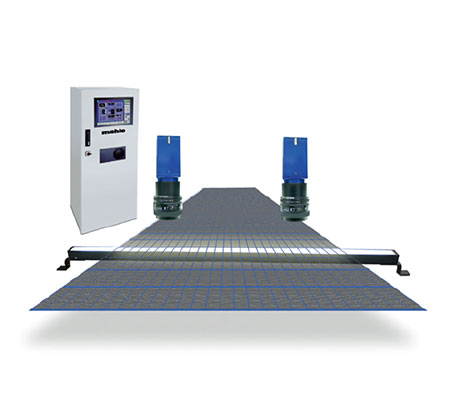

The PCS-12 is the leading pattern detection system using camera technology. The repetitions of printed, woven or tufted patterns are evaluated according to certain algorithms and are used for measuring, correcting, and evaluating distortions and patterns. The system uses one or two cameras, depending on the width of the product, to detect the position of the pattern and automatically and continuously determine the pattern repeat. It also determines the product width, and together with a straightening machine it aligns the product distortion based on the recognised pattern.

Manufactured by: Mahlo GmbH & Co. KG, Germany

-

FEATURES

-

BENEFITS

-

GET A QUOTE

-

Technical Details

- Raw material: versatile Key Features

- Uses camera technology for measuring, corrections and evaluation of distortions and patterns

- Back/reflex lighting, airbag check with back lighting

- Control panel with evaluator, control and display terminal

- Measuring table with mobile camera and lighting

- Can be used for printed, woven or tufted patterns

- Checks the presence of the so called patches on both sides of the airbag by contactless measurement

- Detection and correction of distorted patterns in printed, woven or tufted material

- Uninterrupted monitoring and logging of actual product quality

- Savings in raw materials and energy at the manufacturing stage

- Increased productivity

Your message was sent successfully. Thanks.