PRODUCT

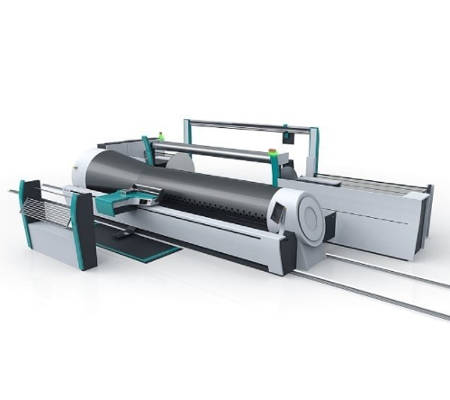

ISOWARP

ISOWARP has been proven to run at higher warping and beaming speeds and, in particular, with a substantial simplification of operation, resulting in improved production. Beam to beam reproducibility is guaranteed with KARL MAYER‘s in-built KAMCOS system, which additionally has easy access to the teleservice network for remote support and machine maintenance.

Manufactured by: KARL MAYER Textile Machinery India Private Limited

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

- Uniform thread tension

- High residual elongation

- Exact thread array

- No crossed ends

- No missing ends

- Produces warps for all the types of fabric qualities i.e. suiting, shirting, linen, sheeting, terry, synthetic, and furnishing applications

- The reverse rotation of the drum is important in ensuring a perfect warp sheet laying at its winding point onto the drum with maximum levelling effect from the evener roller

- Maximum operating speed with optimal yarn tension

- Ensures perfect warp density irrespective of yarn count variations and yarn volume changes

- Simplified working sequence with ease of operation

- Optimum warp build-up on the drum with precise positioning of the reed headstock to the cone is achieved automatically and with the highest precision; reed headstock feed movement is followed automatically

- Uniform cylindrical build-up guaranteed through evener roller

- Ensures optimal winding density with minimal yarn loading

Your message was sent successfully. Thanks.