PRODUCT

Pikaia

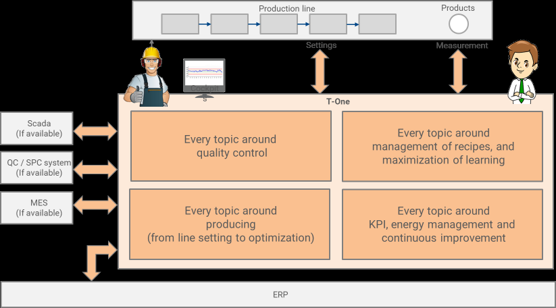

The aim of Pikaia is to provide in one single software, the best possible digital solution for achieving operation excellence with nonwoven processes. Pikaia is unique in the sense it manages all the aspects required to achieve operational excellence, with a special focus on all what is going on in the plant between the equipment and the ERP (Fig). Pikaia is divided into following six modules plus one module for interfacing:

- Quality control and SPC,

- Management of Recipes,

- KPI and continuous improvement,

- Process documentation,

- Monitoring and energy management

- Process optimisation

-

FEATURES

-

BENEFITS

-

GET A QUOTE

-

Pikaia can be interfaced

- With the production line to access to the line settings

- With measurement devices or databases containing product measurements

- With your ERP to display information from your ERP in Pikaia

- With any other software to provide access to data being in Pikaia

-

Module for Quality Control

- Simplifying the quality control activity

- Reducing administrative tasks while increasing transparency

- Having the Quality Control contributing actively to optimization of the process Module for management of the recipes

- Define precisely how your production equipment should be set and checked in order to produce a given item every time.

- This feature alone saves considerable time by maximizing your learnings.

- This module allows you to capitalize on all the knowledge accumulated during each production and allows you to ensure the same performance of the process. Module for KPI and continuous improvement

- This module is monitoring the line speed and compares it with target speed to automatically calculate uptime, efficiency and various other metrics.

- The performance drops are automatically detected and Pikaia offers to explain them in a few clicks. Module for process documentation

- With this module, complicated paperwork is completely eliminated. Moreover, all the relevant information is instantly available and usable. Module for computer assisted process optimization

- Improves the skills of the operators and process managers

- Helps to keep the know-how of your operators in your company

- Improves the performance of the process while constantly ensuring meeting desired quality

- Helps to develop new products faster Module for monitoring the process parameters and energy management

- Helps keeping closer eye on all the process parameters, not only the ones for line setting, but also the less visible ones which are existing inside the production equipment and which may provide interesting insight.

Your message was sent successfully. Thanks.