PRODUCT

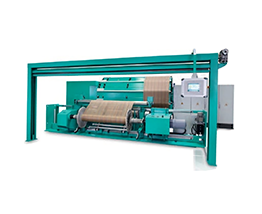

Gir-O-Matic 16S Sample Warper

(Sample warper)

KARL MAYER GOM 16S sample warping machine sets new standards in the warp preparation for sample and production warps up to a warping length of 490 m. A circular creel with 16 winding places guarantees highest efficiency for coloured and solid warps. The unique and patented build-up control provides a perfect build-up of the band.

Manufactured by: KARL MAYER, Germany

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Technical Details

- Application range: shirting, suiting, worsted, silk, home textiles, and apparels Key Features

- KAMCOS SYSTEM operator Interface IPC/touch screen 12.1", ethernet interface for networking and connection for the relevant data acquisition and teleservice

- Processing of silk package and super fine yarns

- Software offers highest convenience of data input and operation

- Patented band build-up system guarantees identical bands also with highly delicate yarns

- Leasing: one or two at beginning and same at the end

- High flexibility and productivity with patterning for perfect beam quality

- Highly efficient production of sample warps and short production warps (reduced time, space, personnel, stock)

- Computer control of all operations including data analysis (network compatible)

- Simple pattern design; input also via an external PC or CAD system possible

- Unlimited number of sampling possibilities

Your message was sent successfully. Thanks.