PRODUCT

Thermex 7000 Continuous Dyeing System

(E-control dyeing range)

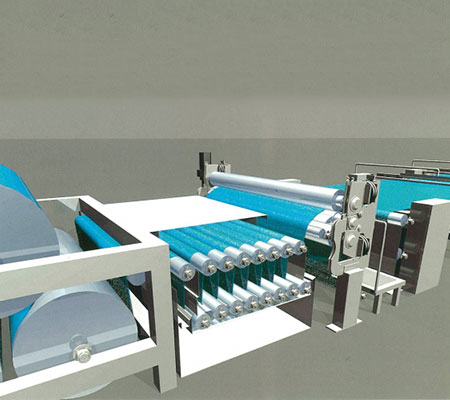

This machine is based on modular design, shortest commissioning times, uniform air delivery, high effective insulation for reduced thermal energy consumption and crease-free fabric passage for wovens as well as knits. Also suitable for e-control for continuous dyeing of woven/knitted fabrics with reactive dyes. Thermex 7000 is a loop dryer offered by Monforts with variable roller pitch to benefit the user in terms of process optimisation speed for different conditions of fabrics run.

Thermex represents a contemporary solution for continuous dyeing and finishing processes. It is distinguished by its remarkable cost efficiency, applicable to both large and small production runs. The incorporation of cutting-edge technology and advanced process engineering allows for the expansion into an extensive continuous dyeing spectrum. The foremost technology in the realm of continuous dyeing is characterised by uniform air control, dependable temperature regulation, and accurate fabric guidance, all of which contribute to migration-free and crease-free drying. This continuous dyeing systems guarantee optimal reproducibility of dyeing outcomes for your operations.

Overall, it serves as a versatile hot flue system for continuous dyeing, condensing, and thermosoling, offering unparalleled reliability even at the highest fabric processing speeds. This system is specifically designed for Econtrol® processes, catering to the continuous dyeing of woven and knitted textiles

Manufactured by: A. Monforts Textilmaschinen GmbH & Co, Germany

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Key Features

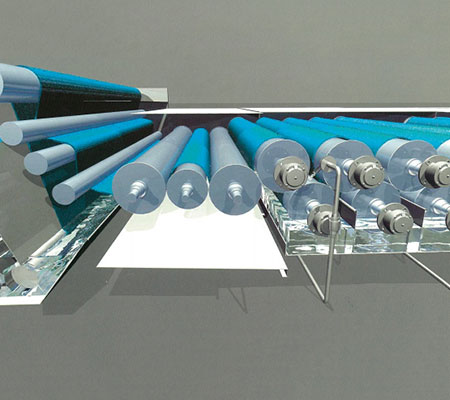

- Thermo-cut system to protect migration of the dye in the selvedge area

- Chamber construction for uniform airflow and temperature

- Infra red pre-dryers (electrical or gas heated) with high evaporation efficiency, variable radiation intensity, constant output with high operational safety and low maintenance

- Tangential airflow across the whole fabric width for uniform fabric finish and drying

- All heating systems including indirect gas heating system – exothermic

- Thermo stretching for denim to control skew with low stretch and less fabric tension

- Modular design to suit customer needs

- Quick cleaning system (optional)

- Dyeing time is only 2-3 minutes

- Zero consumption of salt, sodium silicate, and urea

- Instant shade viewing possibility

- Better color yield due to less hydrolisation of reactive dyes as there is no process of stronger alkali

- Suitable for shorter to longer fabric runs

- Reduces pollution load