KARL MAYER ISOWARP sectional warping: Perfect for fine monofilament yarn!

Warping of fine monofilaments is a sensitive and demanding process. The slightest deviation of any warp parameter from the desired, pre-set value affects the quality of the finished fabrics as it leads to defects such as stripes, irregular fabric appearance, or a wavy weave.

That is why KARL MAYER’s sectional warping technology, a well-proven solution for perfect warping of fine monofilaments, is the preferred choice for this exacting application.

What’s more, KARL MAYER Textile Machinery India can offer the ISOWARP sectional warper that is ideally suited for fine monofilaments, an exact replica of KARL MAYER’s German product.

Monofilaments are mainly used in weaving of:

- Precision fabrics for printing and filter industries

- Home textiles, and

- Fabrics for women's outerwear

While the yarns mainly used are made from PA6, PA66, PP and PES, in the precision fabrics segment the finest yarns of 7 dtex (finer than a human hair) with up to 270 threads per cm are used, which reaches the limits of feasibility in weaving technology.

In home textiles and women's clothing, with the aim to provide best possible textile characteristics, yarns with a trilobal cross-section, in textured form, or yarns which receive special treatment during post-dyeing drying, are used.

Fine monofilament yarns (22 dtex PES) are also processed on ISOWARP for home textiles and women's clothing.

Demands on the warping process during processing of fine monofilaments:

- Regular yarn tension from the creel

- Minimum yarn wear

- Least possible thread strain

- Precise section alignment

- Constant, lowest possible widening of the section of warped threads

- Absolutely cylindrical warp build-up on the warping drum

- Completely identical thread lengths

- Exact thread array

- Elimination of static loads

- No lost threads in the warp

- Digressively adjustable beaming tension

- Maximum productivity with minimum personnel costs

- Simple operation

- Absolutely reproducible

- No snarls in the warp

- No contamination by oligomers

Machine design:

While precision fabrics are mostly woven on machines with a working width of 2200 mm, home textiles normally require a working width of 3400 mm or 3800 mm. Waxing and pressing devices are not necessarily used during beaming, as on the one hand finishes are already applied to the yarns during the spinning process, and a presser device cannot ensure equality of the yarn lengths.

Normally, swivel gate creels with draw-off through the center are selected with the number of positions between 640 and 800. These are equipped with double disc tensioners and in certain cases with an integrated single tensioner blow-off. Either capacitive or electromechanical systems are used for yarn monitoring. Antistatic devices are important in both the creel and the leasing device, and on the warping machine just before the winding point on the drum.

Conditions required for correct warping of fine monofilaments:

In addition to consistent yarn quality, the make-up of the yarns is of decisive importance for optimum warp quality. With precision fabrics these yarns are wound onto cops or bobbins with parallel winding.

For textile applications, precision-wound, short-traverse cross-wound bobbins can also be easily processed on KARL MAYER warping machines. Cross-wound bobbins with a long- traverse and random winding are not recommended as these fine yarns often have pronounced snarling when they are unwound from such bobbins. It is often not possible to prevent such snarling completely even by using sleeves on the bobbins. In such cases, it is advisable to rewind the yarns. An exact length measurement on the supply package is also important, as otherwise it can result into several meters of residual material of such fine yarns.

The requirements for the production environment are much higher than in other branches of the textile industry. Constant temperatures and a constant relative air humidity are critical during the production of precision fabrics. Very fine monofilaments can no longer be warped and woven at temperatures below 20ºC, as uncontrollable changes in the yarn tension occur which only become visible in the finished fabric. Dry air (with a relative humidity of below 60%) increases snarling and the static charge of the yarn. If the yarn is stored for prolonged periods in a room without air conditioning, layers can slough off during warping. Therefore, maximum cleanliness must also be ensured, especially on the thread line. In the event of a high occurrence of oligomers, single tensioner blow-off on the yarn tensioner is essential. Varying yarn tension differences always cause changes in the colour shade and, therefore, result in striped fabric, especially in the case of voile weaves. For this reason, regular tension of the individual threads at the winding point is essential.

Personnel in the warping department must undergo special training for the particular requirements of these yarns. As these yarns are very susceptible to any operating errors and high financial losses can occur as the result of one simple operating fault, specially developed checklists are used to follow exact procedures. For example, during creeling the cops should never be touched on the flank, as this would cause frequent yarn breaks caused by shifting layers. The process is continuously monitored in accordance with quality assurance procedures and the main parameters are checked and logged on each warp.

How KARL MAYER ISOWARP ensures warp quality:

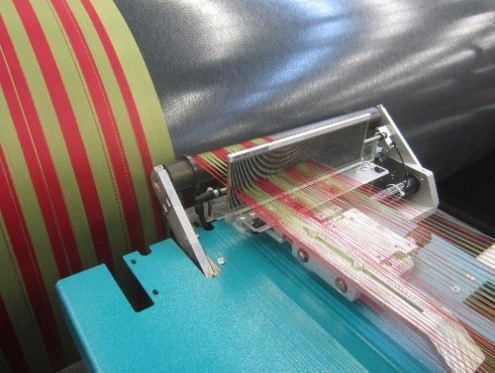

ISOTENS double disc tensioner

Due to the use of calibrated pressure elements, even the variation of the individual pressure springs is eliminated. Strain on the thread is minimised by a special plate surface.

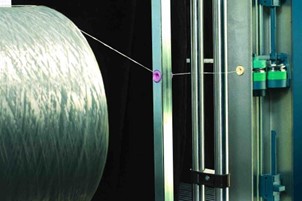

With KARL MAYER’s section tension control, the yarn tension is always maintained at a constant level, irrespective of the bobbin diameter or the warping speed. Due to the inverse direction of rotation of the warping drum and the evener roll, the yarn tension within the section of warped threads is evened further. The yarn tension level should remain constant, depending on the yarn count, between 0.15 cN and 0.40 cN per dtex. For warping of these yarns a simple intermittent draft is recommended on the leasing reed.

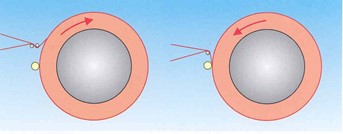

Crêpe pretensioner

The effective elimination of snarls is only possible with a suitable pretensioner, which should not cause any reduction in the warping speed. With the KARL MAYER Crêpe pretensioner, snarls are removed in the start-up phase by diverting the thread at an optimum angle for each yarn type on two pretensioner rods.

Warping drum rotation

Due to the interaction of the yarn tension from the creel, the inverse direction of rotation of the warping drum and the evener roll, compact warp build-up can be guaranteed with minimum strain on the yarn. Even these fine monofilament yarns can be compacted on the drum between 2% and 4%, depending on the yarn characteristics.

Due to the use of a high-precision ball spindle which is also used for machine tool manufacture, precise section alignment is guaranteed, and undesirable stripes occurring in the fabric are prevented. The often-underestimated section width variable is reduced to an absolute minimum due to the short run-up length on the drum and the effective elimination of static charges.

Exact thread array is guaranteed due to the open thread line through to the measuring roll and the short run-up distance to the warping drum. The evener roll ensures that the position of each individual thread is maintained. Short, free thread lengths during beaming prevent rolling ends when the warp beam is wound. Crossed or twisted warp threads can cause tight ends in the fabric, or in extreme cases make it impossible to weave out the warps.

Although almost no yarn breaks occur with fine monofilaments, it must be ensured that no lost threads occur. Due to the very fast response time of the yarn stop motions and the large disc brakes on both sides, very short brake paths are achieved. Should threads still be lost, the position is saved and a stop initiated automatically at the right position during beaming, so that the yarn break can be repaired easily. Pulling the section back during warping would have a devastating effect on the warp quality.

Beaming Unit

During beaming it is extremely important to ensure a correct start. The threads of the warp beams must be covered with paper. Only warp beams of quality Q3 or Q4 (reinforced drum) must be used, as the strain on the warp beam flanges is tremendous. The most important condition for optimum warp build-up on the warp beam is a constant warp tension which must decrease regularly with increasing diameter. Fine monofilament warps are normally wound with a digressive warp tension of 25%. The initial winding tension should have a factor of 1.7 to 2.0 of the warping tension, depending on the yarn count. Further compaction with a presser device is not advisable, as this only has negative effects on the warp quality.

Maximum productivity and simplest operation with absolute reproducibility

The KARL MAYER warping machines achieve maximum productivity with simple, fast retooling from one batch to another as well as the highest warping and beaming speeds.

Simplest drawing-in of ends, positioning of the leases without having to open a top roller, uncomplicated entry of warping data and comprehensive plausibility checks and monitored limit values ensure simple and safe operation of the system.

Exact reproducibility of production has always been essential in the field of fine monofilaments. ISOWARP warping machines not only feature an article memory which saves all necessary production data of a warp and supplies all required information to the machine in the case of repeated jobs, but also a warp data record which is either printed out and supplied with the warp or forwarded to a higher-level operational data logging system.

In summary, it is well established why the features packed cutting edge ISOWARP from KARL MAYER is the perfect technology for processing fine and very fine monofilaments.