PRODUCT

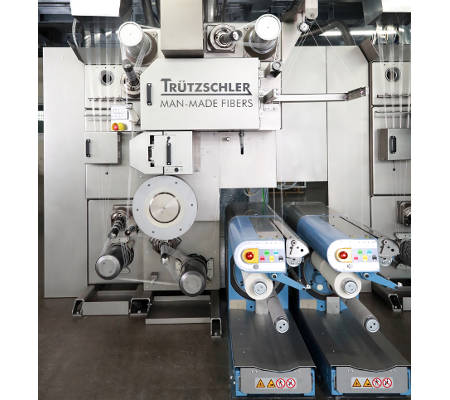

Truetzschler OPTIMA Yarn Production Line

The Truetzschler OPTIMA concept which was designed as a single machine for carpet filament yarn production initially has now evolved into a system platform, with the introduction of the MO40-E. Truetzschler Man-Made Fibers’ Optima range of carpet yarn machines consists of the compact MO40-C extrusion system for standard yarn and the MO40-E for standard and specialty Bulked Continuous Filament (BCF) yarn production.

Manufactured by: Trützschler Nonwovens & Man-Made Fibers GmbH, Germany

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

- Symmetric, straight yarn path: staggered component arrangement minimises turns and angles in the yarn path (MO40-C)

- Compact: small footprint of just 2x2 meters (MO40-C)

- Spin pack for spinning standard BCF qualities (MO40-C)

- Perfect heat distribution: Homogeneuous conditions in both the spin beam and in the drawing zone allow for equal filament properties both between spinning positions and over time (MO40-E)

- Flexible: Bigger spin packs deliver up to 750 single filaments per yarn end. A standard-size spin pack with adapters is perfect for manufacturing standard yarn qualities (MO40-E)

- Spin beam is designed to either house large spin packs for high-count yarns or a combination of adapters and the smaller MO40-C spin pack for spinning standard BCF qualities

- Gentle yarn treatment by proven components, e.g. lamella-free texturing by HPc technology (TO40)

- Tri-colour BCF: each multi-filament is composed of three different colour strands (TO40)

- High output delivered per square meter (MO40-C)

- Energy consumption is one of the lowest per kg of yarn in the entire industry (MO40-C)

- Less filament breaks and constant high yarn and bobbin quality resulting in low conversion costs (MO40-C)

- Top quality yarns, low conversion costs as well as easy handling, and low maintenance (MO40-C)

- Minimises stress on the yarn (MO40-E)

- Exciting colour effects which implements the proven smartFLEX tri-colour process. SmartFLEX BCF yarns are the basis for a broad range of reproducible colour effects

Your message was sent successfully. Thanks.