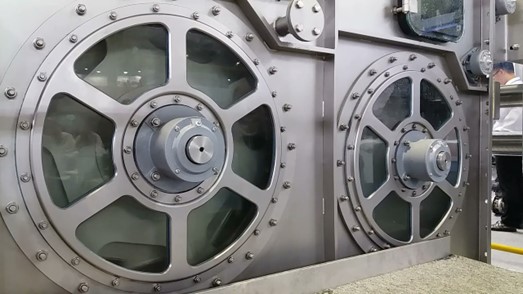

Goller Sintensa Cyclone washing range - First wet process for synthetic fabric production

The world-wide athletic apparel market grew significantly between 2009 and 2022. This market is expected to grow further due to increasing awareness of the benefits of sports and exercise in people’s lives and is estimated to bring in US$ 207 billion in sales by 2025. The impressive growth prospects of the athleisure industry have convinced many synthetic fabric manufacturers to invest in new set-ups as well as increase their production capacities in the last decade. Knit processors – including new players from India and Bangladesh – are expanding and diversifying to meet the needs of this segment. Many investments are therefore being planned to tap the enormous potential presented by this segment.

Garment properties like protection, insulation, moisture permeability, stretch, shape retention, optimum heat and moisture regulation, rapid drying, dimensional stability even when wet, durable, easy care, light weight, soft touch, etc., are intrinsic to active wear garments. However, these properties are not readily achievable in 100% cotton, circular knitted fabrics. Hence the need for synthetic circular or warp knitted fabric production and processing becomes inevitable for addressing the opportunities in the active wear segment.

The very first step in synthetic activewear or spandex processing is spun oil washing. Goller is a renowned manufacturer of wet finishing lines for high-end synthetic fabric manufacturers worldwide.

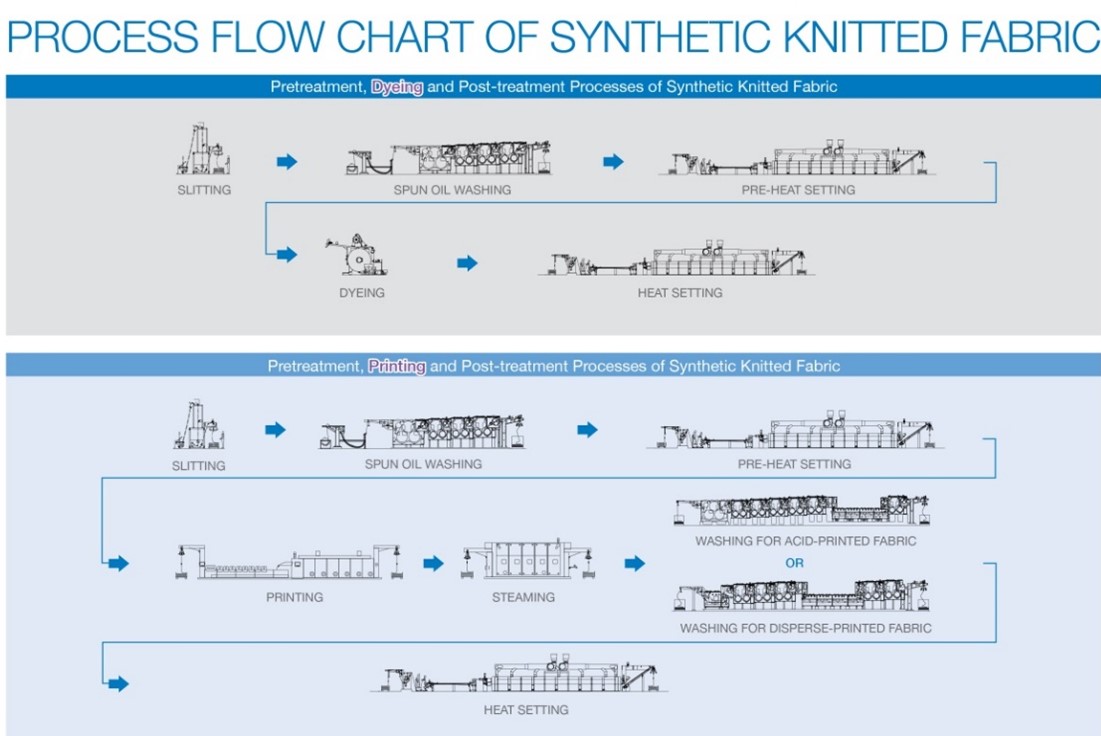

Process flow of synthetic fabric in dye house

Goller Sintensa Cyclone washing range

Objectives of spun oil washing

The spun oil washing process consists of the pre-treatment wet processing of synthetic woven or knitted (circular/warp knit) fabrics with appropriate de-oiling chemicals to remove spun oils from surface of yarn and fabric. These lubricants are needed during the spinning process and remain on the fabric through the knitting process. The purpose of the open width spun oil washing process is to pre-shrink the fabric and reduce and ensure oil distribution on the fabric. This ensures uniform dyeing and finishing results in subsequent finishing steps.

If a grey fabric with oils on it is heat set, there is an accumulation of these oils in the stenter. This creates chances of fire in the exhaust pipelines and in the heat exchangers. Dripping oil further creates quality problems in subsequent processing. But after spun oil washing, if the washed fabric is pre-heated and set, the stenter will remain oil-free and safe, eliminating risks of fire and improving fabric quality.

Benefits of Goller spun oil washing ranges:

- Avoids fire hazard in stenter while pre-setting

- Even dyeing results

- Pre-shrinkage of fabric

- Suitable for wide range of fabrics from light to heavy GSM

- Environment-friendly process

Goller has successfully installed hundreds of high productivity spun oil washing ranges worldwide for processing undergarments, swimming, and activewear. The spun oil washing ranges from Goller are suitable for wide varieties of fabrics – from microfiber to spacer fabric. Some fabrics have a Lycra content of 40% or more, and the weight of the fabric is generally between 40 to 500 GSM in general. End users of such fabrics include Adidas, Calvin Klein, M&S, Nike, Under Armour, Uniqlo, Victoria’s Secret, Wacoal, and other top clothing brands in the fashion market.

Investment in continuous open-width processing requires a lot of knowledge, such as how to control the tension and shrinkage of the fabric, among other things. Goller has a wide range of different modules and a team of skilled engineers that can customise their ranges to meet the specific needs of customers in the field of continuous open width processing. A long history, worldwide experience, and continuous innovation have made Goller a popular choice for continuous open width processing of both woven and knitted products in the industry.

About GOLLER

Goller was founded in Germany and manufacture open width textile processing ranges. Goller became a member of the CHTC Fong’s Group in 2006. The integration of Goller into the CHTC Fong’s Group helped it to develop and spread at a tremendous pace with its highly engineered textile wet finishing ranges for the textile industry. Today, Goller is a global market leader in the manufacturing of open width textile processing ranges and wet processing ranges including those for spun oil washing. These machines are widely used to produce high quality woven and knitted fabrics in textile dyeing factories around the world.