PRODUCT

Blendomat - BO-E

(Compact bale opener for small production areas)

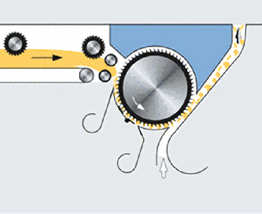

The Blendomat BO-E has been developed specifically for the average production area. Its working width of 1200 mm and compact design ensures that the Bale Opener BO-E takes very little space, less power, while delivering remarkable performance at the same time.

Manufactured by: Truetzschler India Private Limited, India

-

FEATURES

-

BENEFITS

-

GET A QUOTE

-

Technical Details

- Power consumption: 4.95 kW

- Raw material: cotton

- Production: up to 700 kg/hr Key Features

- Huge reservoir with automatic control for filling of material

- Can directly feed cleaner or opener; cleaner or opener can also be bypassed

- Grid bars

- Manually fed: developed specifically for the average production area

- Capacity of up to 750 kg/h

- Feed table length of 2.8 m; extendable

- Provision of suction is possible

- Working width of 1200 mm or 1.2 m

- Thorough opening and initial mixing

- Compact design requires less space

- Feed table length can be extended to 10 m for thorough mixing and long run-times

- Can be optimized for intended application; pre-cleaner integration and bale opener feed via condenser

- Adjustable evener roll ensures additional mixing improvement and uniform tuft size

Your message was sent successfully. Thanks.