We offer a range of magnetic drive process chemical pumps from Iwaki, Japan. Iwaki’s magnetic drive chemical pumps feature rugged ductile cast iron housings with corrosion-resistant liners for the most demanding applications. These chemical transfer pumps are capable of handling highly corrosive liquids and high temperatures.

FEATURES AND BENEFITS

High chemical resistance

Fluoroplastic, fine ceramic and CFRETFE wetted parts offer a high resolution to virtually every industrial chemical handling needs

Patented self-radiation structure

Heat dispersion holes on impeller and magnet capsule force liquid around the spindle and bearing to circulate effectively, reducing the heat generated and preventing thermal deformation. Watch this video to know more.

Non-contact system

These chemical transfer pumps are designed and constructed to prevent contact between the bearing and the rear thrust ring – even if the pumps run dry or in the case of air ingress on the suction side! Damage through heat generation is therefore prevented. Watch this video to know more.

Back pullout system

The pump casing of this process chemical pump is divided into the front casing and the rear casing to form a vortex chamber. Therefore, the internal leak phenomenon (liquid getting out of the impeller returns to the pump casing) is suppressed to a minimum and the liquid is efficiently guided to the discharge port to enhance overall efficiency.

Self-priming option

The SMX-F – a proven chemical transfer pump – requires no external self-priming chambers or valves. The gas-liquid separation design ensures fast self-priming. An exceptional self-priming duration of up to 4 m in only 90 seconds is now possible.

PROCESS CHEMICAL PUMPS – ADDITIONAL FEATURES

100% leak proof pumps, seal-less construction, no shaft seal to maintain/replace

Simple, modular construction for ease of maintenance

Non-metallic chemically inert materials offer excellent resistance to corrosive fluids: ETFE, PFA, CFRETFE, improve thermal resistance and increase durability

Ideal for handling various chemicals including acids and alkalis, as well as high purity chemicals

Iwaki’s magnetic drive process chemical pumps come with non-explosion proof motors. Pump with explosion-proof motors available upon request

SPECIFICATIONS FOR CHEMICAL TRANSFER PUMPS

MXM series

|

Max. capacity | 600 L/min |

| Max. head | 30 m | |

| Material of construction | CFRETFE | |

| Output | 1.5 to 4.0 kW | |

| Temperature range | -10 to 105°C |

The Iwaki MXM is a chemical transfer pump, the design of which offers the best combination of durability, safety and performance for a wide range of chemical process applications. MXM magnetic drive process chemical pumps feature separate impellers and inner magnets which make it flexible for use in a wide variety of applications. MXM chemical transfer pumps are ideal for transfer of liquids such as bleach and sulphuric acid.

MDM series

|

Max. capacity | 1400 L/min |

| Max. head | 74 m | |

| Material of construction | CFRETFE/PFA | |

| Output | 1.5 to 15 kW | |

| Temperature range | -20 to 150°C |

Iwaki’s MDM series of magnetic drive process chemical pumps are designed to solve the most demanding chemical handling applications. Two materials of construction and convenient mounting configuration allows the MDM to handle many aggressive high purity chemical applications. MDM process chemical pumps feature a unique non-contact system design that enable them to withstand dry running compared with conventional magnetic drive pumps that are made of fluororesin.

MDE series

|

Max. capacity | 4000 L/min |

| Max. head | 55 m | |

| Material of construction | ETFE | |

| Output | 4 to 37 kW | |

| Temperature range | 0 to 100°C |

Iwaki’s MDE series of chemical transfer pumps are among the world’s largest non-metallic magnetic drive chemical process pumps, with a maximum delivery of 4000 L/min and a maximum head of over 55 meters. The liquid end parts, plastics are made of advanced corrosion resistant materials such as fluororesins and fine ceramics, and the major fluoroplastic-made parts are reinforced with special metal inserts for added mechanical strength and durability.

MDW series

|

Max. capacity | 5000 L/min |

| Max. head | 98 m | |

| Material of construction | GFRPP, CFRETFE, Aluminiumkeramik, SiC | |

| Output | 11.0 to 75.0 kW | |

| Temperature range | -10 to 120°C |

Iwaki’s MDW series pumps are the largest fluoroplastic magnetic drive process chemical pumps in the world, offering high efficiency and durability for chemical process applications.

SMX series

|

Max. capacity | 440 L/min |

| Max. head | 25.5 m | |

| Material of construction | GFRPP, Alumina ceramic | |

| Output | 0.37 to 4.0 kW | |

| Temperature range | 0 to 80°C |

Iwaki’s SMX series of magnetically driven non-metallic process chemical pumps offer an innovative true self-priming design with no mechanical seals for years of trouble-free service. SMX which is suitable for use as a chemical transfer pump features Iwaki’s self-radiating bearing structure and proven non-contact dry-run capability, which allows it to withstand the rigors of abnormal operating conditions. Utilizing an integral priming and air separation chamber, the SMX series of chemical transfer pumps offer superior and consistent self-priming performance.

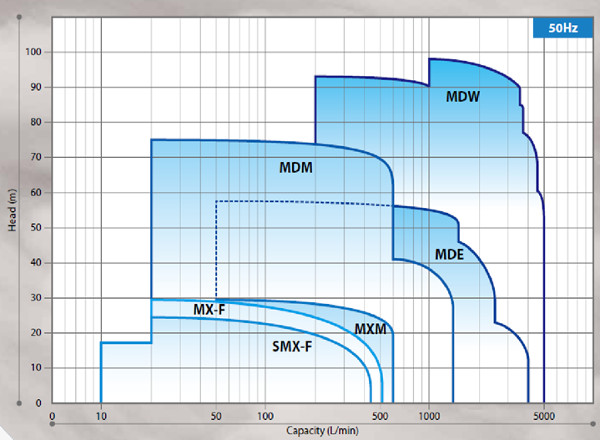

HEAD AND FLOW RATES

Head and flow rates for Iwaki’s M series process chemical pumps

To know more, submit your contact details through the form below and we’ll get in touch with you soon.