PRODUCT

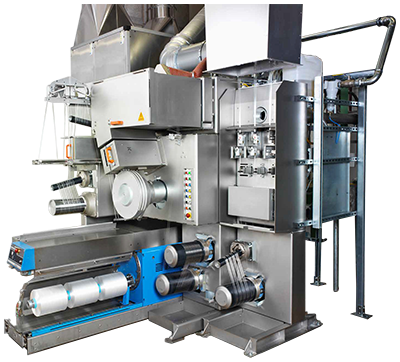

BCF Line

(Thermoplastic polymer extrusion)

SymTTex is a renowned BCF extrusion system in the world of carpet manufacturing. SymTTex systems are available in 2-end, 3-end or 4-end designs. These are highly flexible systems and can process a variety of polymers such as PP, PA6, PA6.6 as well as PET primary granules and recycled bottle material. Now, the already optimised installation can be configured even more accurately in terms of product requirements, available space, and other factors.

Manufactured by: Truetzschler Nonwovens & Man-Made Fibers, Germany

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Technical Details

- Application range: dyed and undyed from fine dpf to coarse dpf BCF yarn for woven carpet, tufted carpet, as well as automotive applications Key Features

- The system allows a complete, easy, reproducible and performing settings

- Highest possible process speed with no differences between the positions

- High crimp, high elongation, with reduced shrinkage and very consistent intermingling

- Large range of yarn count for each application segment

- Finer dpf yarns to allow softer touch

- Pre-assembled and tested plants

- Easy maintenance

- Ready for future upgrades

- Low investment costs for building

- Able to process polyamide 6 & 66, PET and polypropylene

Your message was sent successfully. Thanks.