Any business has the key driver – profitable growth. With plastics industry growing at a 10+ % CAGR growth rate and the per capita consumption of plastics in India being 20% of global majors, there is enough room to grow topline. However, with an attractive market scenario, there are enough processors getting into the business challenging the “profitability” part of the growth.

IoT as a technology play, contributes across the entire value chain for the plastics industry covering sourcing of material, logistics, operational analytics, warehousing, service, etc.

As a solutions provider, one has to understand that there are multiple unfulfilled needs of the industry with a varying degree of value as perceived by the user.

For the purpose of this discussion, it is being limited to plastic processors (end users) as the segment within the Plastics domain.

Value that IIoT brings for Plastic End Users

For an end user, some of the key performance indicators of value are:

- OEE, Availability, Productivity and Quality

- Percent of Production Capacity realized

- Production efficiencies, machine efficiencies

- Downtime, Rejections

- Scrap by type or cause

- Yield with variation from standard

- Energy performance

- Operator performance

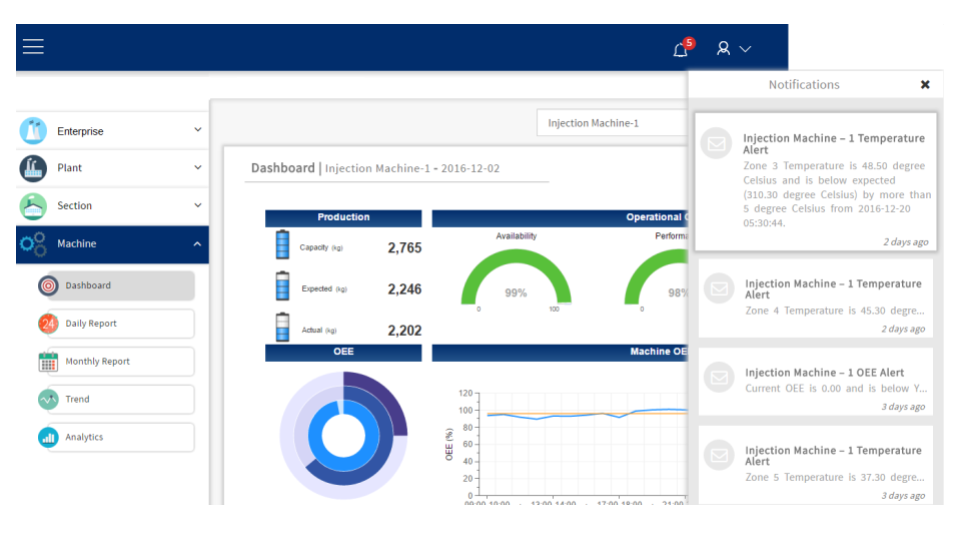

Typically the end users are used to getting data local to the machine – either set of display instruments showing live values or even better via an HMI linked to the PLC. The customer needs additional investments if he or she would like to have “consolidated” view – like a view representing a section of machines in a plant, or complete plant or even sometimes an enterprise view consisting of several plants at different locations.

Many customers have attempted collating information manually into spreadsheets, getting them structured for better understanding and then circulating them amongst stakeholders for reporting. Even though, the customers would have somehow managed this human resource intensive and prone to manual errors process, they still remain far away from assessing and analysing the data that has been collated. This makes decision making slower and not very accurate.

IoT as a technology enabler provides that vital layer of analysis and presentation on anywhere, anytime and any device basis enabling quicker and more accurate decisions.