There are many misconceptions in our minds about Industrial Internet of Things (IIoT). In this article, I will try and simplify basics of IIoT for you. Let’s start with understanding what is IoT?

Googlers define Internet of Things (IoT) as the interconnection of computing devices embedded in everyday objects, enabling us to send and receive data via the internet. I say that is not all. There is a lot more that goes into a complete IoT system. Simply sending and receiving data does not complete the IoT ecosystem as there are limitations of the usefulness of such a system.

To make IoT useful the technology needs to act as a bridge between machines and humans. There is the need for a readable, tangible output in the form of actionable analytics for you humans to complete the IoT ecosystem.

What Is Industrial IoT?

Applying IoT in the industry is called industrial Internet of Things (IIoT). The industries could differ from oil & gas industry to plastics, textiles, power generation, sugar and component manufacturing etc. I have heard others say Industrial IoT will change the way industries function in future; I say that future has arrived. Industry 4.0, the latest manufacturing trend of automation, cyber-physical systems, data collection, storage and cloud computing, heavily uses IIoT for creating the dream of smart factory.

IIoT and its Components

Industries are all about making the most profits from the least possible resources. So, a simplistic IIoT solution would be to measure and understand if the resources are being used efficiently. IIoT helps industries in this process by actively monitoring the process, acquiring and storing data, analyzing it, and providing practical, actionable insights.

So what are the important components of an IIoT system?

- Data Acquisition

- Data Transmission

- Data Management

- Data Analytics

Trust me, the order is important as the output will be void if any of the components fail. Every machine holds a lot of data about itself as it functions. The mystery is to understand how to capture the data. Sensors and electronics help in acquiring the data in a format which can be read and analyzed. Once the data acquisition is done, it needs to be sent to a computer, usually on the cloud, which can process this data.

I wish I could run a profitable data courier service for the machines, but since it is the “Internet of Things”, I’d let the internet do the work. IoT gateways are the devices made to do the job. IoT Gateways collect the data from the sensors, electronics, and PLCs via a communication port and transmits it to the cloud using either GPRS, WiFi, or wired internet.

The advent of cloud has been awesome if you have a smartphone you are already using cloud-based services. I will explain why the cloud is amazing for IIoT in some other article. For now, the cloud provides unlimited storage space and processing power and can receive and store data from millions of devices.

Data management on a computer or cloud becomes very important when your cloud server starts receiving data from millions of machines from hundreds of different makes and models providing critical machine data almost every second.

This data is then run through various algorithms designed for the companies to derive all the required information such as uptime, power consumption, production, productivity, raw material consumption, quality, operator and machine performance, and what not. I always say that this is just the tip of the iceberg, there is a lot more that data can do. Prediction, machine learning, and artificial intelligence are going to change your perspective of data and analytics.

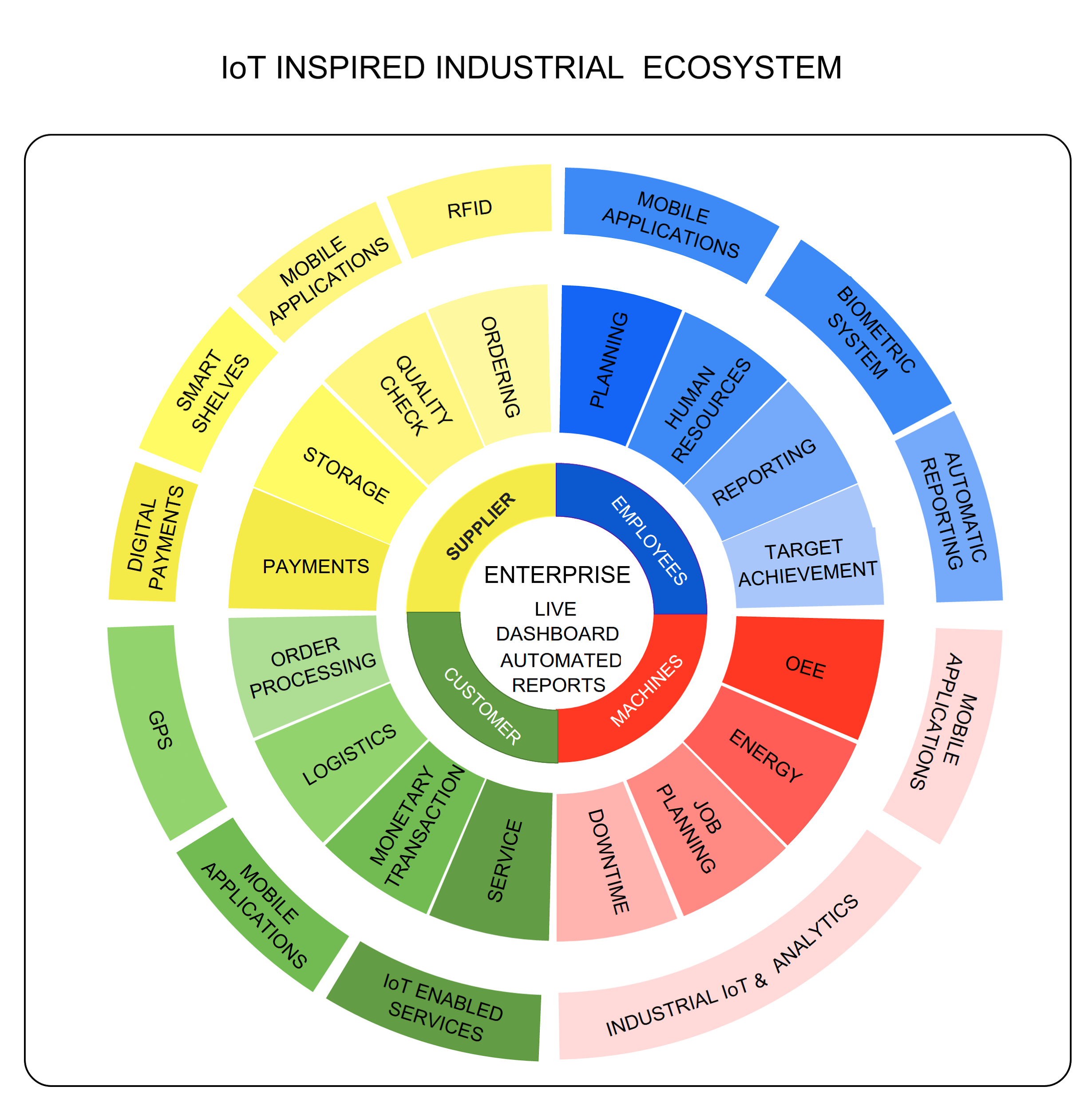

Modern industry 4.0 systems ensure that existing purchase, planning and execution systems (CRM, ERP, and SCADA) are well integrated with IIoT systems so that no data is captured twice by two different systems and so that the newer systems complement the existing system. The diagram at the start of this article shows old and new technologies complementing each other to create a true smart enterprise.

Some IIoT systems are designed for machines to operate without much human intervention, while other systems are designed for humans to be a part of the system. I feel humans are going to be an integral part of the industrial IoT system for planning and supervising machines and systems.

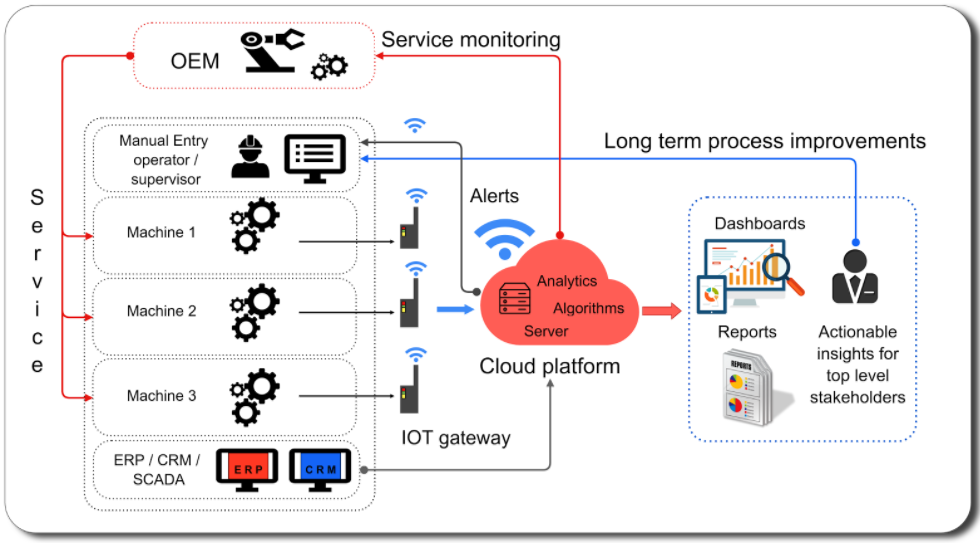

Today’s IIoT Applications

I firmly believe that IIoT will be used in all industries. The manufacturing sector is the leader in making the most out of IIoT. I see IIoT being deployed in many industries such as automotive, FMCG, plastics, textiles, and facilities. OEMs and end users (manufacturers) have both been able to exploit IIoT for substantial benefits. Companies have been able to use IIoT to not only improve their processes and systems, but also provide value added services to their customers using IoT technology. Diagram below shows how OEMs and manufacturers are improving their existing systems using IIoT. I’ll soon cover this diagram in a separate blog.

Industry pundits have pegged IoT market at a trillion dollars within the next decade, where IIoT is expected to be a majority contributor, and with the ability to infuse a 10-15% increase in the global GDP. The developing economies are expected to be the biggest gainers from IIoT owing to the rise of competitive industrialization where profitability will receive a major boost due to the adoption of IIoT.

Interested in more blogs about industrial IoT? Follow me!